The Whats and The Hows of Engine Pistons

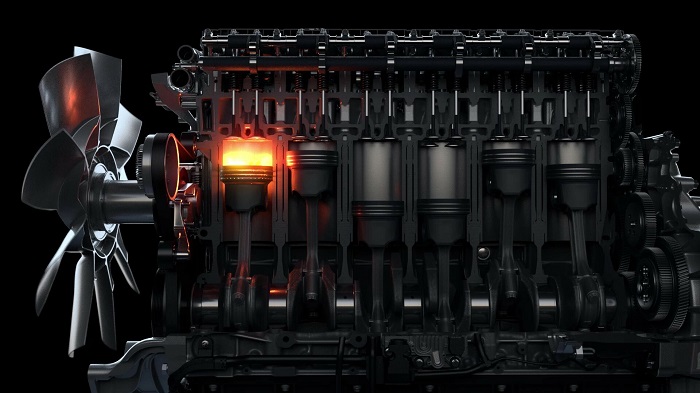

One of the foremost engine parts is the piston. This is a solid piece of metal set firmly in the cylinder. It moves up and down, urged along by the expanding gases from the combustion of air and fuel. Connected by a wrist pin to the connecting rods, and from there, to the crankshaft, the linear movement of the engine pistons acts on the crank journals. This in turn rotates the flywheel and transmission, and what turns the wheels.

This may sound like a simple task, but the forces acting on the piston, the extreme heat and resulting pressure, and the fact pistons complete an engine stroke thousands of times each second, means they need to be built tough. A piston that fails at any speed while moving in the cylinder can spell disaster and completely destroy an engine.

Contents

Piston Parts

All pistons consist of several common parts, despite the variety of shapes, applications and sizes. Engine pistons are comprised of the piston body around which are the piston rings. The piston body itself consists of the piston crown and the piston skirt. The crown is the uppermost part of the piston which forces the whole assembly downward when pressurised by the expanding gases in the combustion stroke. It sits atop an integrated hollowed out part known as the piston skirt. To allow for optimal engine function, the skirt must be sealed within the cylinder walls. Grooves lining the upper part of the skirt accommodate the piston rings and create an air-tight seal. The top or upper compression ring and the bottom or second ring work together in sealing the piston, and are positioned above an oil ring that wicks away any excess oil while also lubricating the skirt as it moves in the cylinder. In addition, the rings help dissipate excess heat. The skirt also has circular holes to fit bushings along which lies the wrist pin. This is the part to which the connecting rod is attached.

How Pistons Work

The task of pistons is to transform linear movement into rotational movement so that the crankshaft and the wheels turn. Pistons are located inside the cylinder walls. In in-line engines, they move up and down, and in boxer engines – side to side. This action is prompted by the heat created from the compressed and ignited mixture of air and fuel released into the cylinder head by the intake valves. As the piston moves down it acts on the connecting rod and reaches its lowest point, known as the bottom dead centre or BDC. This is the power stroke. The intake valves are closed at this point, and the piston makes its way up the cylinder wall. The remaining gases are pushed out of the cylinder head through the exhaust valves that open just as the piston reaches its highest point, or top dead centre. The whole process is a cycle, involving four engine strokes – compression, ignition, combustion (power) and exhaust.

Materials in Engine Pistons

The pistons in early combustion engines were made of cast iron because of their perceived strength and longevity. With advancements in materials, these have been replaced by lighter aluminium alloy pistons, with trace components, particularly silicon. This has reduced overall weight and allowed pistons and engines to reach higher speeds. Today two grades of aluminium alloys are used. 2618 alloys contain a lower silicon volume, allowing for higher expansion rates in increased loadings. These are preferred in higher revving engines in performance cars and can bear repeated abuse without failing. Standard 4032 aluminium pistons have a higher overall silicon content and are more ideal for lower to medium engine loads, where a tighter seal and less noise are more important than performance. The piston and wrist pins are made of iron or steel alloys allowing for high strength and hardness.

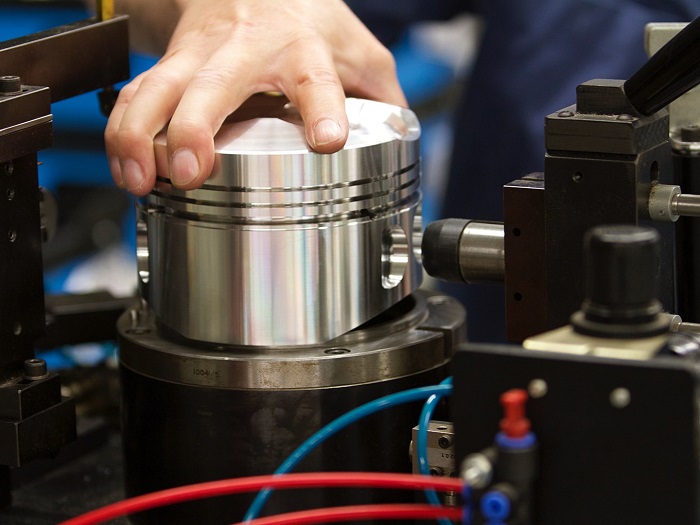

Piston Types by Production Process

The basic distinction here is between cast and forged pistons. Casting involves pouring liquid metal into a preformed mould. Forging is the process of controlled deformation of the aluminium alloy into the preferred shape by applying pressure. Forged engine pistons are generally of higher quality and strength and are the type used in performance engines. They have better resistance to wear and fatigue during higher heat levels. The downside in forging is that there is more machining involved in perfecting the shape of the final product and this makes forged pistons more expensive.

Buying Considerations

Depending on the intended application there are different pistons to choose from. Cast pistons feature with high silicon content are found in most stock engines and here, for the intended task of everyday driving are more than adequate. However, if you intend on rebuilding or increasing power in stock engines, forged pistons in 2618 alloys are the way to go. They can handle higher revs better and won’t crack or shatter as temperatures rise. Though generally heavier than cast pistons, the forging process allows for better structural integrity, and therefore strength. If installing a turbo during the rebuild then definitely opt for forged pistons.

Pistons are often paired with other engine components, particularly matching connecting rods, for your engine. Variations in piston design, materials and types will affect the overall performance gains over stock parts. Expect to shell out a little more when going the forged route.