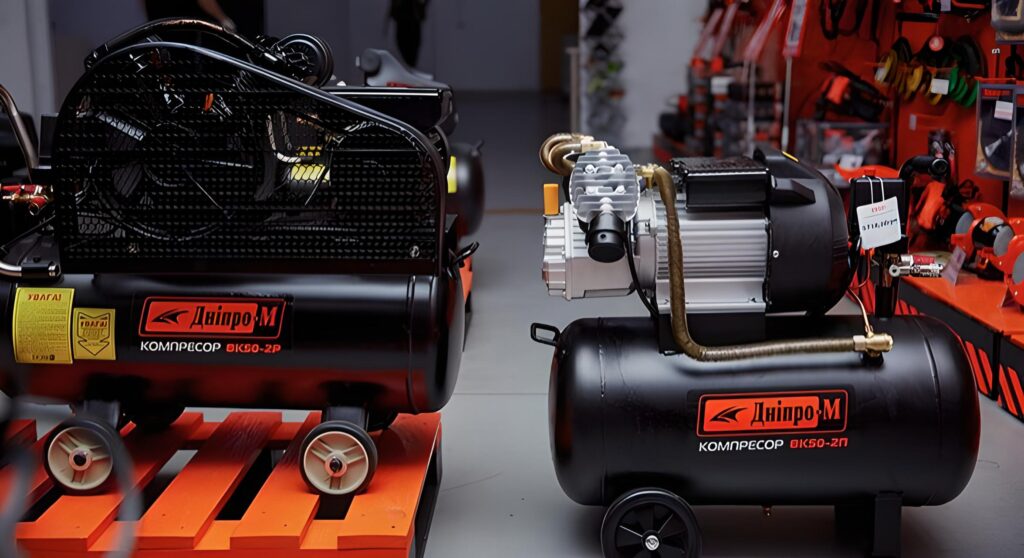

Belt Drive vs. Direct Drive: Choosing the Right Industrial Air Compressor for Your Needs

When it comes to industrial air compressors, the debate between belt drive and direct drive configurations has raged on for a long time. Each option comes with a set of advantages and considerations, so it’s crucial to consider you needs and preferences before deciding. Whether you’re powering pneumatic tools on a construction site, maintaining critical systems in a manufacturing facility, or anything in between, the performance and reliability of your compressor can make or break your productivity.

Contents

Advantages of Belt Drive Compressors

If you’re in the market for an air compressor and you come across a belt drive petrol air compressor for sale, these devices use a belt and pulley system to power the air end. This belt connects the machine’s motor to the air pump, which operates the pistons or rotors. As the motor turns, it powers the belt, which then transfers power to the air end via the pulley system. Most piston air compressors utilise this belt-driven setup.

So, what makes belt-driven petrol compressors stand out? One major advantage is their flexibility. By adjusting the belt and pulley configuration, you can change the CFM (cubic feet per minute) and PSI (pounds per square inch) ratings of the machine. This flexibility is particularly handy for facilities that may need to alter their pressure requirements in the future, such as woodworking or auto repair shops. Plus, these machines are often more affordable upfront compared to their counterparts.

The pulley system can translate motor RPM into air pump speed. By tweaking the pulley and belt setup, you can adjust the maximum pressure and airflow of the machine. However, it’s essential to note that these variables are inversely related – you can’t increase both at the same time without changing the motor’s horsepower. For instance, you could trade off some PSI for more CFM by adjusting the pulley configuration.

Aside from their flexibility, a belt drive petrol air compressor for sale offers other advantages too. The belts are relatively simple to maintain and replace, which makes service a breeze. While you may need to check and change belts more frequently, it’s a task that a professional maintenance team can easily handle.

Advantages of Direct Drive Compressors

In a nutshell, a direct-drive petrol compressor connects the motor directly to the air pump via a crankshaft. As the motor kicks into gear, the crankshaft springs into action, driving the pistons (for reciprocating compressors) or turning the rotors (for rotary-screw compressors). The speed of the motor directly dictates the speed of the air pump, and consequently, the airflow (measured in CFM).

These machines can be either geared or ungeared. In ungeared setups, the air end’s moving parts always match the motor’s speed precisely. Geared versions, on the other hand, offer some adjustability by tinkering with the gear configuration. While this flexibility comes at a cost, it’s a handy option for manufacturers who want to standardise motor sizes across machines with different horsepower and CFM ratings.

So, why might you opt for a direct-drive model? Well, for starters, they’re simplicity personified. With fewer moving parts compared to their belt-driven counterparts, they boast enhanced reliability, efficiency, and lower maintenance requirements. Without belts to replace, you’ll spend less time and money on upkeep over the compressor’s lifespan. Thanks to their direct connection, there’s minimal power loss between the motor and the air end. This translates to reduced electricity consumption compared to belt-driven models of similar horsepower. And hey, who doesn’t love saving a few bucks on their energy bill?

Finally, direct-drive petrol air compressors are tough cookies. Their belt-less design makes them more resilient in harsh environments, whether they’re subjected to scorching heat or bone-chilling cold. So, if your machine is destined for a rough-and-tumble setting, a direct-drive model might be your best bet.

How Do I Choose the Right Air Compressor?

Usage

How much air will you be pumping, and how often? Do you need a constant stream of airflow or just occasional bursts? Understanding your CFM requirements and usage patterns is crucial here. For heavy-duty, continuous use with high CFM demands, a direct-drive rotary screw compressor is your go-to. They’re built to handle the pressure and deliver consistent performance day in and day out. On the flip side, if your air needs are more modest and you anticipate fluctuating CFM requirements down the line, a belt-driven compressor might suit you better.

Price

Budget is also a major consideration, as these machines are a big investment. While belt-driven models typically come with a lower upfront cost, don’t forget to factor in lifetime expenses. Direct-drive compressors often require a heftier initial investment, but their lower maintenance costs and longer service life can lead to significant savings in the long run.

Environment

You should also consider the environment in which your machine will operate. If it’s going to be exposed to extreme temperatures or corrosive chemicals, a direct-drive model is the way to go. Belts in belt-driven compressors are sensitive components and don’t fare well under harsh conditions, leading to more frequent maintenance and downtime.

Upkeep

When it comes to maintenance, both types are simple to maintain. However, direct-drive models come with fewer belts to inspect and replace, so they require less hands-on maintenance. On the other hand, when these machines need maintenance, it’s often more specialised and expensive compared to belt-driven models. Consider your maintenance capabilities and downtime costs carefully before making your decision.